الوصف

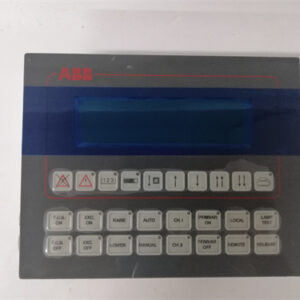

The ABB 3ASC25H216A DATX132 DCS PLC Module is part of ABB’s 800xA Distributed Control System (DCS) and is designed for high-performance process control in various industrial applications. Below is the detailed information you requested.

Product Name:

ABB 3ASC25H216A DATX132 DCS PLC Module

Product Description:

The ABB 3ASC25H216A DATX132 is a modular I/O interface designed to integrate seamlessly with ABB 800xA DCS and S+ Control systems. The module is used for the precise monitoring and control of processes in industries such as oil & gas, chemical processing, power generation, and manufacturing. This module handles digital and analog I/O signals, ensuring high reliability, fast response times, and operational safety.

As a part of the DATX132 family, this module is specifically engineered to provide flexible integration options, high scalability, and built-in redundancy to meet the stringent requirements of mission-critical systems. The module supports a wide range of industrial communication protocols and is designed for use in both standard and hazardous environments.

It is widely used in distributed control systems (DCS) to ensure robust control of operations, helping users to achieve high efficiency, reliability, and system availability.

Product Parameters:

- Model Number: 3ASC25H216A DATX132

- Type: Distributed Control System (DCS) I/O Module

- System Compatibility: Compatible with ABB 800xA DCS and S+ Control.

- Input/Output Types: Digital I/O, Analog I/O, and Specialized I/O (depending on the configuration).

- Redundancy: Designed with redundancy for power supplies and communication channels.

- Protocols Supported: Supports industrial communication protocols such as Modbus, PROFIBUS, and Ethernet/IP.

- Hazardous Area Certification: Suitable for use in both hazardous and non-hazardous industrial environments.

- Application Areas: Oil & Gas, Chemical Processing, Power Generation, Manufacturing.

Specifications:

General Specifications:

- Module Type: Distributed Control System (DCS) / Programmable Logic Controller (PLC) I/O module.

- System Compatibility: Works with ABB 800xA DCS and S+ Control platforms.

- Operating Temperature Range: Typically -20°C to +60°C (-4°F to +140°F).

- Humidity Range: Typically 5% to 95% relative humidity, non-condensing.

- Power Supply: 24V DC (may vary depending on configuration).

- Mounting: Suitable for DIN rail or rack-mount installation.

- Protection Class: Typically IP20 for industrial control enclosures.

Electrical Specifications:

- Input Voltage: 24V DC (depending on configuration).

- Power Consumption: Typically around <20W (depending on the configuration and I/O load).

- Redundant Power: Features redundant power supplies for increased system reliability.

- Communication Protocols Supported:

- Modbus

- PROFIBUS

- Ethernet/IP

- Additional proprietary ABB protocols for enhanced compatibility.

Functional Specifications:

- Input/Output Types:

- Digital I/O: Supports discrete inputs and outputs (for binary signals such as relays and switches).

- Analog I/O: Supports continuous signals (e.g., for measuring temperature, pressure, level, flow).

- Specialized I/O: Can be configured for specific I/O requirements such as HART, Foundation Fieldbus, or other advanced sensors.

- Real-Time Control: Provides real-time control of industrial processes, critical for industries like power generation, chemical processing, and oil & gas.

- Redundancy and Fault Tolerance: Redundant power supplies and communication channels ensure the system stays operational even in case of a failure.

- Advanced Diagnostics: Built-in diagnostic features help identify faults and potential failures early, minimizing downtime and ensuring system uptime.

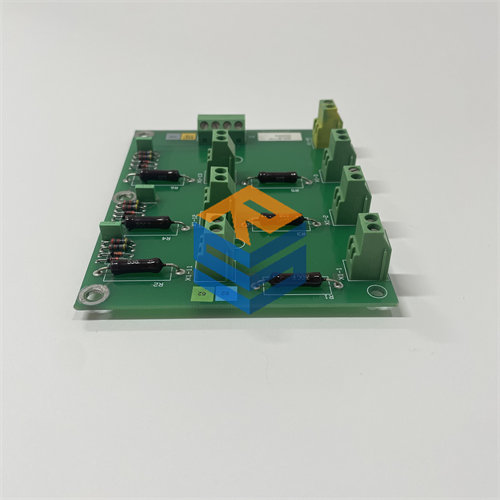

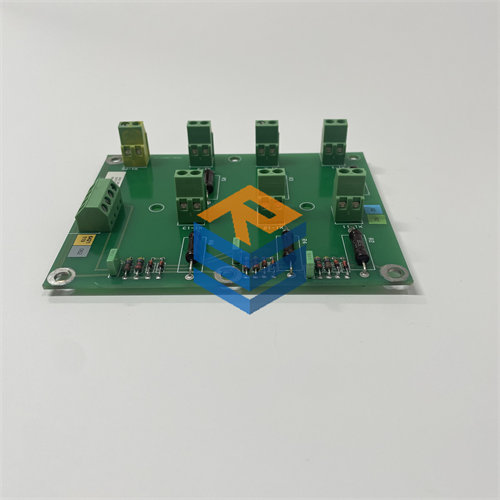

Mechanical Specifications:

- Dimensions (approx.): Around 140 mm x 120 mm x 90 mm (height x width x depth). Exact dimensions may vary based on specific configurations.

- Weight: Typically around 1.5 kg, but may vary depending on configuration.

- Housing: Metal or plastic housing designed for industrial control environments.

- Connector Type: Typically uses screw terminals or plug-in connectors for secure wiring.

- Mounting Type: Can be mounted on a DIN rail or in a rack-mounted enclosure.

Safety and Compliance:

- Explosion-Proof Design: Suitable for use in hazardous environments, compliant with ATEX or similar certifications.

- Protection Class: Typically IP20, meaning it is protected from objects larger than 12mm and is intended for installation in control cabinets or other enclosures.

Key Features and Advantages:

- Modular and Scalable: Allows easy integration and scaling of I/O requirements for complex control systems.

- Redundancy for High Reliability: Built-in redundancy for power supplies and communication ensures system reliability.

- Flexible Communication Options: Supports industry-standard communication protocols like Modbus, PROFIBUS, and Ethernet/IP for easy system integration.

- Wide I/O Support: Capable of handling digital, analog, and specialized I/O signals, making it highly adaptable to various industrial control needs.

- Advanced Diagnostics and Maintenance: Provides advanced diagnostics and health monitoring for system integrity and proactive maintenance.

- Designed for Hazardous Areas: Meets the requirements for use in hazardous environments where explosion-proof and high-reliability solutions are needed.

- High Precision and Real-Time Control: Capable of real-time process control with high precision and minimal delay, suitable for critical applications in industries like oil & gas, chemical, and power generation.

Applications:

- Oil & Gas: In offshore platforms, refineries, and pipeline monitoring for ensuring safe and continuous operations.

- Chemical Processing: For chemical plants, controlling and monitoring chemical reactions in real-time to ensure process stability.

- Power Generation: In power plants for controlling turbines, monitoring generators, and managing energy distribution.

- Manufacturing: In industrial automation for controlling production lines, robotic systems, and assembly processes.

- Hazardous Environments: Meets the standards for use in explosive atmospheres or areas with strict safety requirements.

Conclusion:

The ABB 3ASC25H216A DATX132 DCS PLC Module is a versatile and reliable solution for industrial process control, offering flexible communication protocols, high scalability, and redundancy to ensure robust system performance in demanding environments. It is well-suited for industries such as oil and gas, chemical processing, power generation, and manufacturing, providing critical real-time control, safety, and system reliability.

jiedong@sxrszdh.com

jiedong@sxrszdh.com +86 15340683922

+86 15340683922 +86 15340683922

+86 15340683922